Our Technology

Capturing and Delivering Flavors in a Smarter Way

We embarked on an intellectual journey to achieve superior flavors. Instead of rewriting the rules, our innovators strategically leveraged them to revolutionize outdated flavor delivery technology that had seen better days.

We take pride in our exceptional team, cutting-edge technology, and our portfolio of patents. Our relentless pursuit of excellence has resulted in substantially reduced usage rates, optimal levels of flavor actives, minimal oxidation, and enhanced aroma delivery. Our clients get pretty jazzed about that.

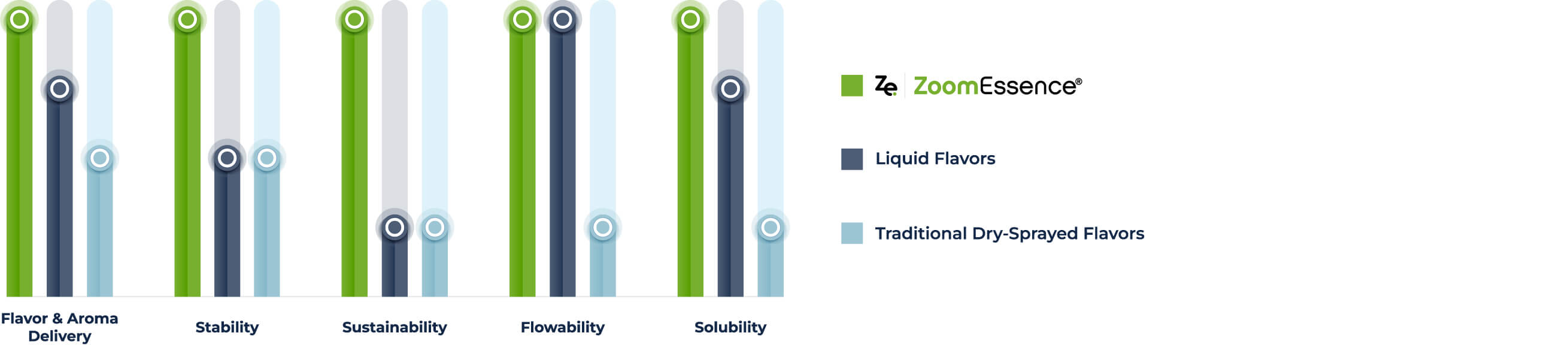

Zooming Delivers: Better Flavor by Every Measure

Stack our flavor delivery technology side by side with the traditional powder and liquid flavors and see what you get.

Significant Differentiation Compared to Existing Flavor Companies Driven by a Delivery System Technology

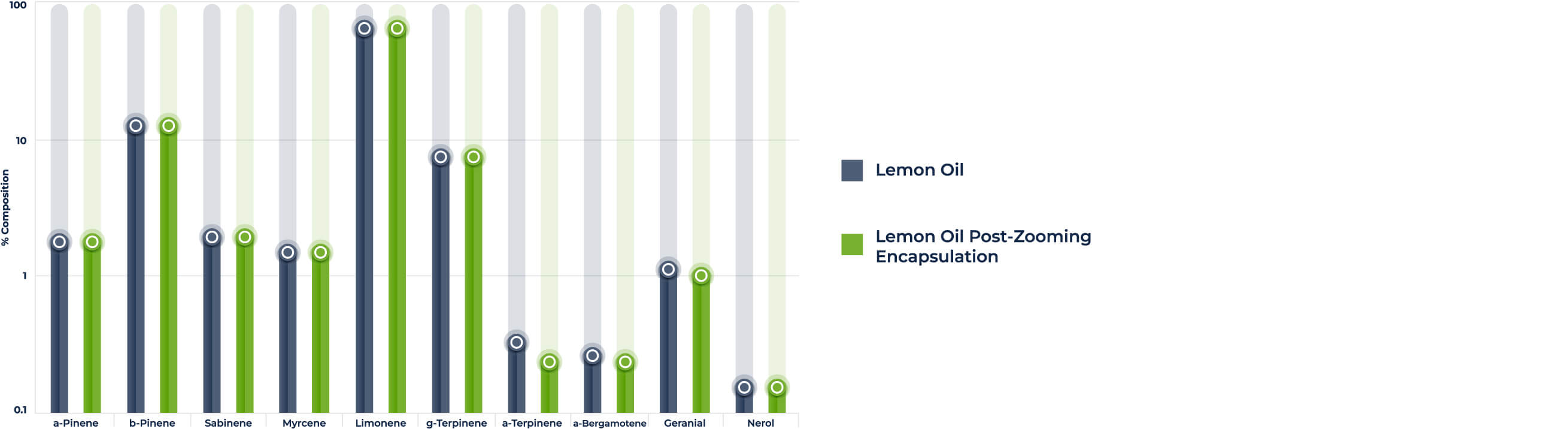

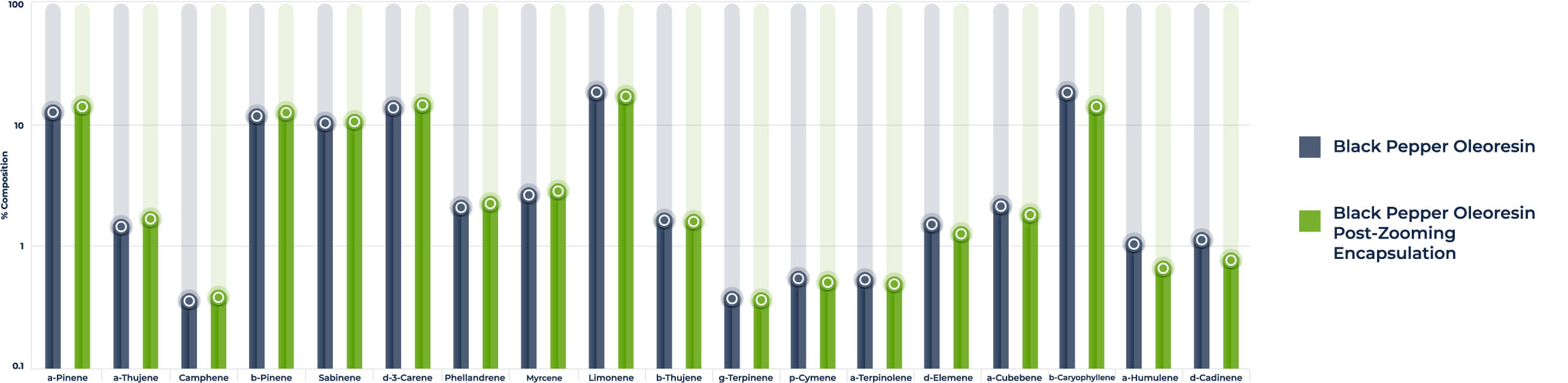

The Zooming technology delivers what nature intended, molecule by molecule. Below are two examples highlighting how the aroma and flavor naturally found in citrus and black pepper oils can be encapsulated. We tested the important compounds that drive the consumer experience to ensure they can be protected and delivered in your food and beverage. The technology enables us to pass the test everyday.

Lemon Oil Gas Chromatography Retention Analysis

Black Pepper Oleoresin Gas Chromatography Retention Analysis

How It Is Made

Low temperature is the cornerstone of Zooming® technology.

It is why our encapsulation process delivers unparalleled aroma and taste without compromising the authenticity of the ingredient. Low temperatures minimize evaporation and distortion of flavor compounds. We retain 95 – 100% of the starting flavor materials

This ability to capture all the “good stuff” is critical when it comes to delivering highly authentic and highly aromatic flavor experiences.

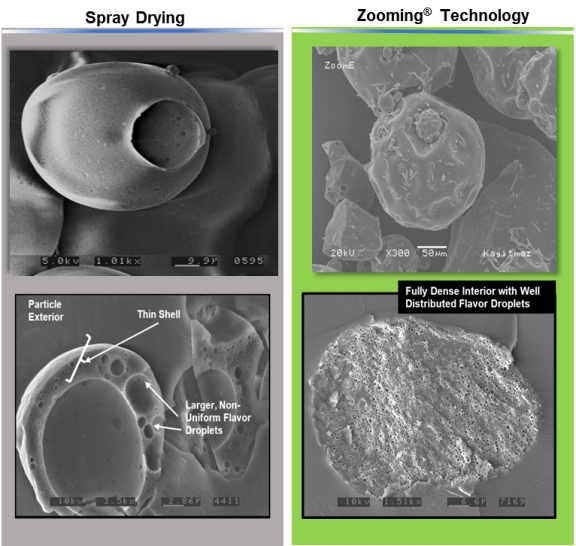

Zooming Particle Attributes

Size: Ranges from 80 to 120+ microns. Significantly larger than spray dry (40–60 microns), creating larger more dense powders with improved flowability and solubility.

Density: Low-temperature drying kinetics help form fully dense particles without air pockets or hard outer shell for superior solubility and shelf life protection.

Concentration: Formulations are engineered with higher active loads and minimum diluents. Zooming flavors and ingredients are built for maximum efficiency, driving use rates and costs lower.

Low Surface Oil: The high solids formulation supports improved emulsification, reducing surface oil and the oxidation of active components.

Stability: Low heat, low surface oil and larger particles promote significantly improved shelf life.

Let’s Talk

About Your Next Project

"*" indicates required fields